Do you wish to use resin for your project? Then the choices of resin available to you are many, each offering their own pros and cons. We are going to concentrate on Polyurethane Casting Resin. In this guide, we are going to show all of the most important properties and show you what to be careful of when purchasing your Polyurethane Cast Resin.

What is Polyurethane Casting Resin?

In broad terms, Polyurethanes are plastics or synthetic resins that are a product of a polyaddition reaction involving polyisocyanates, dialcohols or polyols. Polyurethane Casting Resin comprises a broad spectrum of characteristics that differ from operation to operation and spans a large range of options. This in turn produces elastomers, thermoplastics as well as thermosets.

In other words, Polyurethane Cast Resin is a 2-part system consisting out of a resin and a hardener, which after mixing causes a chemical reaction and forms a hard-solid surface. PU Casting Resin can also be blended with filling materials, colorants and numerous additives just the same as any Polyester Resin or Epoxy Resin. This enhances the properties, for example, when adding an inhibitor, it will increase the resins pot life or processing time. This property can enable you to vary the application to suit your needs for your project.

Things like color pigments will give your PU Casting Resin amazing colors and designs. You can then transform the resin to meet your specific requirements. Some of the fillers you can use are glass fibers, cotton flocks, lightweight fillers and mineral fillers. By making use of these fillers, you will be able to impact certain properties like surface hardness, mechanical strength, or stiffness.

Pros and Cons of PU Resin

For any project, you should check to see if the type of resin you choose is suitable for your project. In most cases, the PU resin has numerous benefits and only a few drawbaacks.

Pros

- The viscosity is so that you can easily work with it and has good flow properties

- Easily blended and applied

- PU resin hardens fast and the demolding time is short

- Insulates electrical equipment

- Excellent filling capacity

- Can create small and thinned-walled models, which are highly stable

- You can blend in a variety of fillers or additives from colors to inhibitors

- When curing there is only slight shrinkage

- High heat resistance once cured

- Depending on the make-up of the PU resin, you can get thermosetting plastics and elastomers. The later can be added by a vulcanization process after curing.

Cons

- You cannot weld once cured

- Certain additives need to be included to produce UV-resistance

- The resin is prone to moisture, which can lead to unwanted effects like foaming

- While curing, a strong odor is produced that can be a health risk

- PU resin has lower adhesive qualities than Epoxy resin

PU resin is known as a fast-curing resin, meaning it can be processed and unmolded fairly quickly. To work efficiently, you will need to consider the pot life of PU resin. If you do not, you will find the resin hardening too quickly, and you will have to start all over again. However, some see this as an advantage as it also means a quick demolding time.

Depending on what project you decide on, you should consider the level of hardness and if it will be suitable for what you want to do. You should be able to see the Shore hardness results on the resin packaging. The hardness measurements are determined by either the Shore A scale (softer) or Shore D scale (harder).

Areas where PU Casting Resin can be Applied

The field of application for PU Casting Resin is extremely varied; it is an amazing material and is used extensively by the DIY enthusiast as well as the professional in the industrial sector.

Here are some examples that PU Resin produces; adhesives, paints, coatings and foam. Not only does it produce these items, but it also protects electronic fabrications from numerous environmental effects like moisture or mechanical stress. For this reason, they are typically encapsulated.

Furthermore, PU Resin is used in producing:

- Spring and damping elements

- Instrument transformers used for high and medium voltage

- Many wearing parts, casting tires and drive elements

All surfaces where you want to apply liquid PU Casting Resin must be completely dry before you apply. However, when used in the production and formation of foam, water is needed for the required reaction. If this is not properly adhered to, then the PU Casting Resin could lose most of its desirable properties.

Floor Coatings

Polyurethane Casting Resin has found its home in many industrial buildings, for example, halls used for various types of gatherings, or auto workshops and factories. The main reasons being that it is visually appealing and acts as protection for the floor, whether it is concrete or other floor coverings. Apart from being a highly effective floor covering, it also has other characteristics such as its elasticity and resistant to abrasion. It can also hold up to heavy loads like machinery as well as high temperatures. Another good attribute is that it is fairly cost-effective and is also easy to apply.

If you want to apply resin outside, then we recommend the use of Polyurethane Casting Resin over Epoxy Resin. As the PU Resin will not yellow easily because of its high UV resistance, as well as its ability to hold up against severe temperature changes

Another popular application for PU Casting Resin is at schools, as it reduces the possibility of the children slipping and having accidents. When flat roof surfaces are renovated then PU Casting Resin is often used, as it is quite easy to apply and is also strong and long-lasting. In this type of application, its UV resistant property plays a vital role.

Casting Molds Using Polyurethane Casting Resin

Because PU Casting Resin has a low viscosity, it is ideal for use in casting molds, irrespective if the molds are used only once or are reusable. When you cast your mold, mix both liquids and then pour the mixture into your mold, leave for a time to harden. When you are casting the PU Resin into the mold you need to consider these two points:

- With PU Resin, you may damage your master mold, as the curing process causes extremely high temperatures

- You will not be able to remove your PU Casting Resin from the mold unless you first treated it using a release agent

Here are some mold casting applications to consider:

- When restoring buildings and monuments, casting is used

- Used in glazing or coating of various items

- In the manufacturing process for electronic circuits where assembly, insulator and semiconductor components are encapsulated

- Where reservoirs, watercourses and pools are reproduced

- Model making

- With cables where open contact points are potted

- Transparent sealing and wrapping of certain perishable items

The casting of molds is extremely popular amongst many users and can be done by hand as well as by machines. To avoid too many bubbles forming during pouring, the 2 components of the PU Casting Resin must be carefully mixed. Then pour very slowly into the mold.

If there are still a few air bubbles visible after pouring, gently tap the mold with your fingers a couple of times to allow the bubbles to escape. If you have a problem with air bubbles another option is for you to fill the mold from the bottom rather than pouring the resin into the mold from the top. When used on a larger scale, for example, in the industrial sector, the castings, as well as the casting compounds, get dried by using a vacuum and are also degassed before they are used.

Step by Step Tutorial for Processing PU Casting Resin

The way that PU Casting Resin is processed is largely dependent on its planned use. In this, our Polyurethane Casting Resin Guide, we will be accepting that its use is for a concrete floor covering and also a mold casting.

Mold Casting

If you are going to use your PU Casting Resin for mold casting, the first thing you need to do is prepare all the materials you will need. This is important as the 2-Part resin has a limited processing time. If you are not sure of how much processing time you have, mix a smaller amount or if you are going to cast a large mold, then add an inhibitor.

Floor Casting

If you are going to use the resin for a floor covering, then the floor surface needs to be properly prepared before you start. This means it must be thoroughly cleaned and free from any grease, dirt, or dust. Any cracks or joints need to be filled first and the whole floor must be level. Remember, allow the levelling compound to dry completely before you apply the PU Casting Resin. Now that you have prepared the floor correctly, you can commence with priming. The ideal solution is to use a 2-Part Primer specifically for use with PU Casting Resin without any solvents.

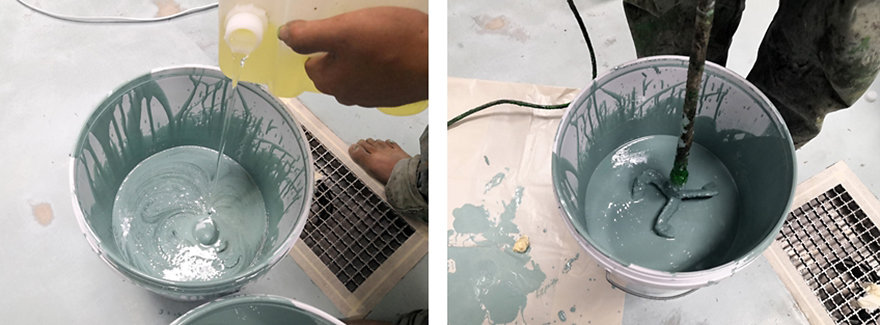

Mixing Instructions

- If you are using or working with a 2 Component PU Casting Resin, it is time to mix them

- When using a single element resin compound, you can ignore this step

- You must adhere explicitly to the manufactures instructions on the container when mixing

- Make certain that you stir the two compounds thoroughly and pour them more than once to make sure they are completely blended

- Once you have completed the mixing properly, your Casting Resin is ready to be poured into your mold, but first, ensure your mold has been treated with a release agent beforehand

- If you are pouring a floor covering, then you need to pour a thickness of about 1/4 inch or less depending on the condition of the floor and also the amount of traffic it has to carry

Curing Process

- Now it is time to allow your resin to cure, which will take around 24 hours. However, you need to leave it for around 72 hours before you put anything heavy on it or allow heavy traffic over it

- Available today, are hot-curing as well as cold-curing resins

- Many PU Casting Resins can be cured by using ultraviolet light from a UV lamp

- You need to take extra care when you are using your PU Casting Resin for large areas, as you may find shrinkage in fairly big areas taking place. If this does happen, you can re-cast the area, but this will not be possible if the resin has completely cured, as it could result in cracking and internal stresses building up

- While the resin is curing take note of any excessive heat being given off by the chemical process. If the heat does not properly dissipate, the temperature of the casting will carry on rising and this will accelerate the curing process, which can cause weak spots in your material

- After the resin has completely hardened you can then take it out of the mold

- Clean the casting ensuring all the release agent has been removed

- The casting can now be primed and painted

- If the casting is to be used outdoors ensure that it is properly painted to protect it from the suns UV rays, as well as the weather conditions

Storage Instructions for Polyurethane Casting Resins

When you store your PU Casting Resin, make sure that it is not subjected to big temperature fluctuations. The normal storing temperature for your PU Casting Resin is 15 – 25° C when the resin is still in a closed container. When you open your PU Casting Resin, make sure that the packaging is still moisture-proof and airtight. Once you open the container work quickly and shake the 2 part components carefully before you mix them thoroughly.

Note: If you find the PU Casting Resin has crystallized slightly while in storage, just warm it carefully by not exceeding 70° C and it will de-crystallize. You then need to wait for it to cool down and come to around room temperature, then you can process it further.

Safety Instructions when Processing your PU Casting Resin

- Some additives you use may be harmful to your health, like flame retardants or plasticizers

- The PU Casting Resin contains Isocyanates, which can cause allergic reactions and could also result in cancer. Not to worry, as these properties are only applicable to the material that has not yet cured properly. As soon as the material has cured, it poses no more health hazards, but use caution when you handle your PU Casting Resin

- If you get some of the mixture in your eyes or nose, rinse them thoroughly with water and make an appointment with your doctor

- Keep the resin away from open flames

- When working with PU Casting Resin always ensure that you follow the manufactures instructions on the containers

- Wear protective equipment when working with PU Casting Resin such as latex gloves, goggles, respiratory mask and long-sleeved shirts. Ensure that the area you are working in is properly ventilated and all the tools you need are close at hand

Questions and Answers

What is Polyurethane?

Polyurethane is not an epoxy but is a plastic or synthetic resin and we come into contact with it every day.

For example:

- Low-density flexible foam utilized for bedding, upholstery for car seats and home use

- Hard solid plastic utilized for electronic instrumentation

- Low-density elastomers utilized in footwear

- Various types of castings for military, industrial, agricultural and automotive markets

- Flexible plastics utilized for bands and straps

PU resin boasts many beneficial characteristics that are used professionally and at home. Polyurethane is formed by an exothermic polyaddition reaction (heat-releasing). So, you can see Polyurethane is an amazing material, which is utilized in the industrial and also domestic fields. Due to its easy application and other constructive characteristics, it will provide you with a perfect finish even if you have no prior experience or knowledge working with it.

Can you safely Use Polyurethane in the Kitchen?

Yes, Polyurethane is safe to use on wooden countertops and as such is classed as food safe. The FDA clarification of food-safe is that the product must be fully cured and dry to the touch. To obtain this takes time, which can range from a few days to a month.

Is Polyurethane Food Safe?

According to experts, resins once they are fully cured, are food safe. Even Polyurethane Varnish does not pose any health hazard. Take note that no resin is food safe until it is fully cured, which is, as a rule, 30 days or one month at 65 to 75°F (normal room temperature).

Can Polyurethane be Applied over Resin?

Yes, but you need to first apply 2 or 3 coats of Epoxy Resin and then you can apply one clear coat of 2-Part Polyurethane finish. This type of finish or coating is beautiful as well as long-lasting.

Can you Remove Polyurethane by Using Vinegar?

No, you cannot remove it but it can soften it or damage the surface. It has been proven that by using undiluted vinegar you will kill 90% of bacteria and also 80% of viruses as well as mold. The vinegar needs to be applied and left to soak for a long time. However, vinegar is not the solution for Polyurethane, even diluted it will soften the Polyurethane and ruin your beautiful floor covering, making it more vulnerable to scratches and water damage.

What type of Polyurethane is better to use on Countertops?

First, paint your countertop and allow the paint to dry and harden. Then you can apply a coat of Clear Polyurethane Resin, which is the best to use on your countertop. However, Clear Polyurethane Resin created specifically for floors is more durable and scratch-resistant than Clear Polyurethane Resin created for use on wood and other related applications.